Conference theme and tracks

The theme of IMKL2026 is "Beyond automation: your roadmap for human-centric digital transformation".

Under this theme, the conference programme is structured into four core tracks:

1. Future of Manufacturing

2. Global trends in manufacturing digitalisation

3. From vision to value: Realising digitalisation

4. Overcoming obstacles – pathways to your digitalisation journey

IMKL 2026 Conference agenda

Conference Day 1 (13 May 2026, Wednesday)

Session 1: Future of Manufacturing

| 09:15 - 09:30 | Opening remark |

| 09:30 - 10:00 | Keynote: This keynote traces the milestones of smart factory development: from modular “LEGO brick” interoperability and digital twins to the rise of service-based communication standards. Looking ahead, Prof. Zuehlke explores how AI and generative AI will orchestrate supply chains and adaptive production in real time, while cybersecurity and human responsibility remain decisive. The session underscores the importance of equipping both young and experienced workers with interdisciplinary skills to thrive in a dynamic, IT-driven manufacturing world. |

| 10:00 – 10:20 | Industrial Metaverse & Quantum Computing: The Next Frontier Building on the journey from smart factories to Industry 5.0, this session looks ahead to the next frontier of industrial innovation. The industrial metaverse promises immersive, interconnected ecosystems that transform collaboration, training, and operations, while quantum computing opens unprecedented possibilities in optimization, simulation, and materials discovery. Together, these breakthrough technologies extend the vision of digital transformation—offering ASEAN manufacturers and global leaders a glimpse into how tomorrow’s factories will be designed, operated, and sustained. |

10:20 – 10:40 |

Declaring Industry 5.0: Unlocking the Power of Human-Centric Digital Transformation This session declares Industry 5.0 as the new paradigm shaping global manufacturing, where the focus moves beyond automation to human‑machine collaboration, sustainability, and resilience. It will explore how this transformation is already influencing industries worldwide, with particular attention to ASEAN and Malaysia’s evolving role in the global value chain. By framing the opportunities and challenges of this new era, the session sets the stage for the following panel discussion on whether ASEAN manufacturers are truly ready to embrace Industry 5.0. |

| Coffee Break | |

| 11:10 - 11:20 | Benchmarking ASEAN’s Digital Readiness: Insights from SIRI Assessments This session presents fresh regional data on ASEAN manufacturers’ digital maturity, highlighting Malaysia’s position within the broader landscape. The insights provide a clear baseline for understanding where industry players stand today and set the stage for the panel discussion on Industry 5.0 readiness. |

11:20 - 12:00

|

Panel discussion:

|

Session 2: Global trends in manufacturing digitalisation

| 12:00 – 12:20 | Key Enabling Technologies (KETs) for the Future of Manufacturing: Roadmaps & Platforms |

| 12:20 – 12:40 | From Reactive to Proactive: AI Agents Shaping The Future of Manufacturing As manufacturing faces increasing complexity and volatility, AI agents are emerging as powerful enablers of predictive decision‑making, adaptive production, and resilient supply chains. This session explores how AI agents move factories from reactive problem‑solving to proactive intelligence—anticipating disruptions, optimizing processes in real time, and strengthening competitiveness. Delegates will gain insights into how these digital actors are reshaping the future of manufacturing and accelerating the global digitalisation journey. |

| Lunch | |

| 14:00 – 14:20 | Resilient and Sustainable Supply Chains with Digital Twins & Predictive Analytics Supply chains are under increasing pressure to be both resilient and sustainable. This session explores how digital twins and predictive analytics enable real‑time simulation and data‑driven insights to anticipate disruptions, optimise operations, and strengthen responsiveness. Beyond resilience, these tools also support sustainability metrics—tracking energy use, emissions, and waste reduction—helping manufacturers align competitiveness with ESG goals. Delegates will gain a practical view of how digitalisation technologies are transforming supply chains into adaptive, intelligent, and sustainable ecosystems. |

| 14:20 - 14:40 | Intelligent Robotics: From Enabling Technologies to Human‑Centric Machines Robotics is where enabling technologies meet the factory floor. This session explores how advances in AI, digital twins, and predictive analytics are converging to create intelligent, adaptive robots that extend human capabilities and reshape manufacturing ecosystems. By bridging frontier technologies with real‑world applications, the discussion sets the stage for deeper dives into polyfunctional robotics and humanoid robot development—highlighting how these innovations will redefine productivity, collaboration, and sustainability in global manufacturing. |

| 14:40 – 15:25 | Panel discussion: Manufacturing ecosystems worldwide are evolving to balance competitiveness with sustainability, offering valuable lessons for ASEAN. This panel brings together global and regional perspectives to share successes and failures in building sustainable factories and supply chains, highlighting the barriers that persist and the opportunities ahead. By examining real‑world case studies, delegates will gain practical insights into how ASEAN manufacturers can adapt global best practices to local realities—laying the groundwork for deeper discussions on digitalisation barriers and pathways to transformation. |

| Coffee Break | |

| 16:00 – 16:40 | Breakout sessions: Deep dive into common digitalisation barriers: Track 1) Digital skills gap Track 2) ROI accessment to implement digitalisation Track 3) Data management Track 4) AI applications |

| 16:40 – 17:00 |

Sharing of findings by individual groups |

Conference Day 2 (14 May 2026, Thursday)

Session 1: From vision to value: realising digitalisation

| 09:15 – 09:35 | Supply Chain Resilience in Practice through Digitalisation for Competitiveness With rising material costs, geopolitical tensions, and supply disruptions reshaping global trade, manufacturers are under pressure to make their supply chains more competitive and adaptive. This session examines how digitalisation can deliver practical advantages—from improving supplier visibility and responsiveness to leveraging predictive analytics for pricing, sourcing, and risk management. By focusing on competitiveness rather than sustainability, the discussion highlights how manufacturers can use digital tools to reduce costs, secure supply, and build stronger partnerships. Delegates will gain actionable insights into how resilient supply chains can become a strategic differentiator for ASEAN manufacturers in today’s volatile market. |

| 09:35 – 09:55 |

Industrial 5G: Turning digitalisation into measurable value Industrial 5G is moving from pilots to production across Malaysia and ASEAN. This session focuses on how manufacturers can translate 5G into measurable value—improving real‑time visibility, automation, and responsiveness through private networks and edge‑enabled applications. Drawing on regional best practices and Malaysia’s expanding portfolio of use cases, speakers will share concrete deployment lessons, KPIs, and pathways to scale—turning connectivity into competitive advantage. |

| 09:55 – 10:25 | AI-Driven Production Optimization: Accelerating the Journey to Zero Waste Factories This session explores how AI-driven Production Optimization can accelerate the transition toward zero‑waste manufacturing by 2030. By unifying machine data, process conditions, and energy usage into real‑time analytics, manufacturers can eliminate material waste, reduce rejects, and improve efficiency while delivering measurable ESG outcomes. Drawing on use cases from electronics, food processing, and high‑mix environments, the paper demonstrates how digitalisation translates vision into tangible value—boosting competitiveness and sustainability for Malaysia’s manufacturing sector. |

| Coffee Break | |

| 10:55 - 11:15 | Securing Intelligent Systems: Guardrails and Observability for Trustworthy AI in Manufacturing As manufacturers adopt AI to drive competitiveness, resilience, and automation, ensuring that these systems remain secure, reliable, and aligned with business goals becomes critical. This session explores how to implement guardrails, observability tools, and governance frameworks that prevent AI from going wrong, whether through bias, mis‑decision, or cyber vulnerabilities. Speakers will share practical approaches to embedding trust into intelligent systems, from monitoring AI agents in production to securing digital twins and robotics. Delegates will gain actionable insights into building trustworthy, human‑centric AI ecosystems that deliver measurable value without compromising safety or integrity. |

| 11:15 – 11:35 | Scaling AI in Manufacturing: Lessons from Pilots to Plant‑Wide Deployment This session explores how AI-driven Production Optimization can accelerate the transition toward zero‑waste manufacturing by 2030. By unifying machine data, process conditions, and energy usage into real‑time analytics, manufacturers can eliminate material waste, reduce rejects, and improve efficiency while delivering measurable ESG outcomes. Drawing on use cases from electronics, food processing, and high‑mix environments, the paper demonstrates how digitalisation translates vision into tangible value—boosting competitiveness and sustainability for Malaysia’s manufacturing sector. |

| 11:35 – 12:20 | Panel discussion: Cobots are gaining traction in Malaysia and ASEAN as manufacturers seek practical automation solutions, while humanoid robots are advancing rapidly in AI and complex manipulation. One year after IMKL 2025’s debate, this panel revisits the question: which is the best fit for manufacturing today—and are we ready for humanoids yet? Moderated by Dominic, the discussion will assess the progress made in the past 12 months, compare real‑world cobot deployments with emerging humanoid use cases and explore why certain applications may require supports from robots. Delegates will gain a clear view of current realities, future pathways, and the readiness of ASEAN manufacturers to embrace the next wave of robotics. |

| Lunch | |

Session 2: Overcoming obstacles – pathways to your digitalisation journey

| 13:50 - 14:20 | Pitching session 1: Solution Providers on Digital Skills & Workforce Upskilling |

| 14:20 - 14:50 | Pitching session 2: ROI & Financing Models for Digitalisation |

| 14:50 - 15:20 | Pitching session 3: Data Management & AI Integration Solutions |

| Coffee Break | |

| 15:50 – 16:15 | ROI in Digitalisation: Why Manufacturers Invest and How Returns Are Realised When manufacturers embark on Industry 4.0, understanding both the why and the how is critical. This case study highlights a successful digitalisation journey, sharing the rationale behind the investment, the implementation steps taken, and the timeline required to achieve measurable returns. It addresses common misconceptions that ROI is immediate, showing instead how gains are unlocked through continuous improvement, integration, and workforce alignment. Delegates will gain practical insights into setting realistic expectations, planning the right activities, and ensuring digitalisation delivers sustainable value. |

| 16:15 - 17:00 | Panel discussion: To conclude the two‑day program, this panel brings the conversation full circle by returning to the central theme of human‑centric digital transformation. While automation and intelligent technologies are reshaping manufacturing, the true measure of success lies in how they empower people. Panelists will explore practical strategies for ensuring that digitalisation enhances human capability rather than replacing it, from workforce empowerment and skills development to designing systems that prioritize safety, creativity, and collaboration. By reflecting on insights shared across the conference, this closing discussion will highlight how manufacturers can move beyond automation to build resilient, competitive, and human‑centered ecosystems for the future. |

*Updated as of 6 Feb 2026. The conference schedule and speakers are subject to change.

Advisory committee

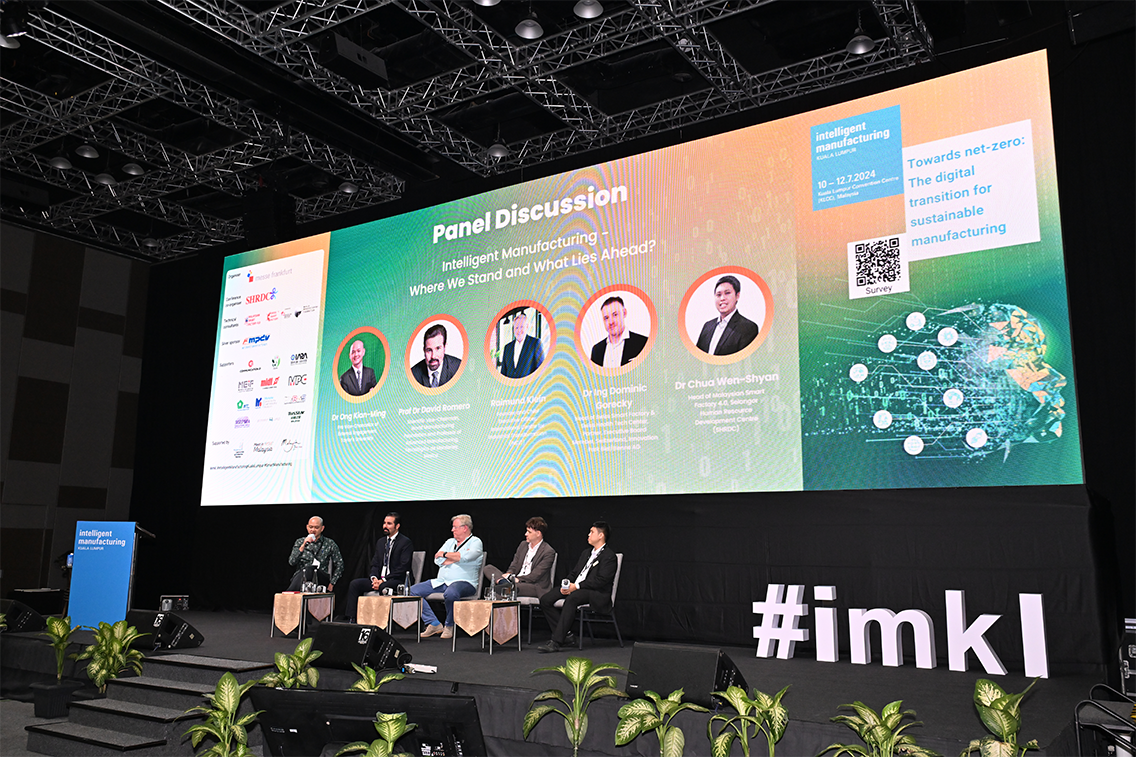

IMKL 2025 Speakers

Past conference agenda

Contact us

If you are interested to become a speaker or sponsor for this event, please feel free to contact:

Ms Jenny Ma

Tel: +852 2238 9914

Email: jenny.ma@hongkong.messefrankfurt.com